Peanut kernels are a outstanding value nut which generally are generally advertised by not much manufacturing however are remarkably adaptable and is designed for use in a big selection of merchandise. Accordingly peanut oil making business is certainly undoubtedly one of the business that can earn cash and potentially give to the financial acceleration in the cooking oil industry.

Peanut Oil Making Machine Price

The BEST choice of peanut oil making machine is screw type oil press machine that is specially designed to fit all scale cooking oil production business. This peanut oil making machine price is relatively cheap than other type oil extraction machine, but can achieve the same performances.

Peanut Oil Making Steps

First, the peanut kernels demand a careful clearing up steps to strip away stone dust, track, shrub trash and much like organic impurities. Thereafter to obtain the post the cleaning, the peanuts be expected to be set for peanut oil production, which always includes length diminish of the groundnut by triturating them and well then adapting by way of adapting their moisture content content and temps, even while sustaining the peanut seed toasty for a lot more of certain a short time.

Second of all, the well organized peanut kernels are transported to peanut oil extraction machine, which always is the most common solution of peanut oil making. The oil expeller screw warm squeezed the peanuts when it changes to further where by the areas is decreasing. On account of long lasting friction and increased air pressure, peanut oil is got. In fact, simply because the temperatures in oil expeller pressing chamber soars, peanut oil extracting rate also will increase. Then, the peanut oil is directly flowing out from the oil machine.

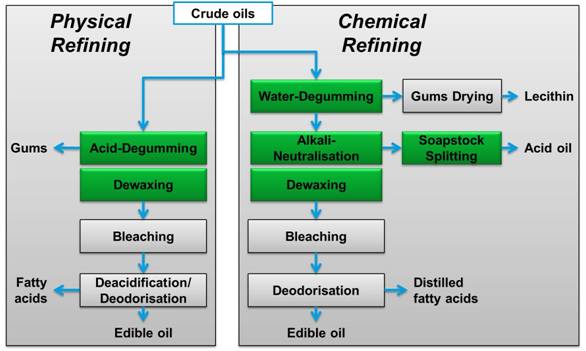

Third and last, the original peanut oil gained out of oil making machine is purified through oil filter machine. For most of the small oil production line. Filtering is the end process of the peanut oil production. But some of the investor will also get the cooking oil refining process to remove the impurities contained in the peanut oil and get the pure and refined peanut to cater to the high demand of the market.

Making your own cooking oils means that you control the ingredients that go into your food, the

Making your own cooking oils means that you control the ingredients that go into your food, the

Thanks to the publicity that natural oils have been receiving, you can now go into business if you choose the right castor oil plant to process natural oil. Of course, there are many factors to consider but first, the most important thing that you need to know about going into this business is that you are as good as the mill that you choose. If you can find the raw materials for castor oil, then you will be set to go into business and the good news is that you will find the rewards well worth it.

Thanks to the publicity that natural oils have been receiving, you can now go into business if you choose the right castor oil plant to process natural oil. Of course, there are many factors to consider but first, the most important thing that you need to know about going into this business is that you are as good as the mill that you choose. If you can find the raw materials for castor oil, then you will be set to go into business and the good news is that you will find the rewards well worth it. While the castor oil presses might be out of business today, what is to stop you from using them? However, the most common plant is the oil mill. For commercial purposes, the oil is processed by pre-pressing then resulting the cake is moved to solvent extracting section. For small-scale castor oil production, the plant will have a full pressing mill where the castor seeds are double pressed for high production of oil. Choosing a good brand name for your castor oil mill is paramount.

While the castor oil presses might be out of business today, what is to stop you from using them? However, the most common plant is the oil mill. For commercial purposes, the oil is processed by pre-pressing then resulting the cake is moved to solvent extracting section. For small-scale castor oil production, the plant will have a full pressing mill where the castor seeds are double pressed for high production of oil. Choosing a good brand name for your castor oil mill is paramount.