The determination to save and protect the planet earth is slowly being entrenched in the minds of the people. The immediate evidence can be witnessed in the palm oil mill effluent treatment that is being encouraged in all solvent extraction plants. There are some companies that have established the palm oil mill effluent (POME) treatment section to ensure that every raw effluent produced is handled and processed with care so that it becomes useful and less harmful to the environment. It is estimated that a ton of fresh fruit bunches are capable of producing 0.65 tons of all raw palm oil mill effluent (POME).

This statistics is an eye-opener in the sense that unless such quantities of POME are treated, they could contribute to further environmental pollution. The process of treating POME is a slightly complicated process that requires total understanding of the main processes that are involved. At first, POME is subjected to anaerobic digestion that takes two phases. Once these two phases have been successfully accomplished, it is taken through the extended aeration process. The anaerobic process is important in the sense that it destroys the pollutant in the POME while the extended aeration process seeks to ensure that the pollutant level does not exceed the Department of Environment (DOE) requirement.

In the past people used to extract oil manually but this has changed over the years although in some countries they still use the traditional methods of oil extraction. In order to produce high quality oil from oil bearing products, it is recommended that you consider using the solvent extraction plant. In addition, it is capable of extracting large quantities of oil provided that you know how to use it well. There are some solvent extraction plants that are able to extract high quality oil at extremely low temperatures under a vacuum.

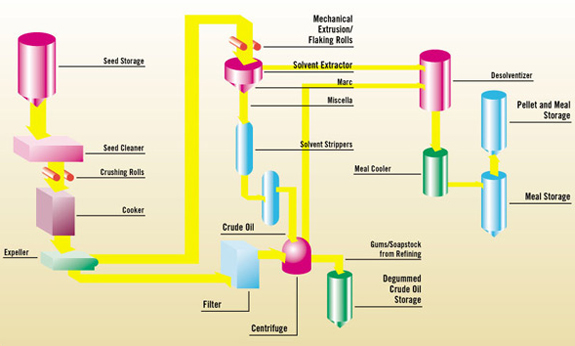

However, there are others that rely on the conventional mechanical pressing under high temperatures and pressure. Though most solvent extraction plants still continue to use the mechanical pressing, the sad news is that when you extract oil at high pressure and temperature, it is susceptible to oxidation. This implies that the final product will be compromised and will not be as pure and excellent as the one that has been produced at low temperatures in a vacuumed environment. The process of solvent extraction is taken through a chain of the following steps though they are not the same in all solvent extraction plants:

- Preparation

- Extraction

- Distillation

- Meal toasting

- Recuperation

- Meal finishing

Solvent Extraction Process

May 17th, 2012 | Posted by in Process Of Edible Oil Extraction - (Comments Off)Though it may appear like an obvious process, the solvent extraction process is an abstract process in the minds of the layman. Consumers are mainly concerned with the final product but they do very little to understand the process. This process involves extraction of oil from materials that produce oil using a solvent. The most commonly used solvent is hexane, a petroleum byproduct. This process is made possible with the help of solvent extraction plants. The particular oil in question is extracted using chemicals through a series of processes.

It is important to understand each of these processes because any mistake that you make could jeopardize the final product that you intend to produce. The basic raw material for oil extraction is the cake which is derived from the press section of the solvent extraction plant. This cake is then dissolved using an organic solvent after which this solvent is evaporated. In order to cut down on the cost of purchasing the organic solvent, it is usually recycled. If you have future plans of establishing a solvent extraction plant, you need to ensure that you have done your research well and that the staff that you recruit is professional and vast experienced in this area so that you can realize its full benefits.