The cotton seed oil tank is used for storage in the solvent extraction plant. There are two basic types of oil tanks: the crude tank and the product tank. The crude tank moves large quantities of unrefined crude oil from its point of extraction to refineries. The product tank is generally much smaller and is designed to move edible oil from refineries to points near markets. (Read more about Cottonseed Oil Mill Project Cost)

Our highly cost effective cotton seed oil is supplied on very large scale. Our Cotton Seed Oil is remarkable for its quality and is processed under the guidance of experts. We are committed to serve quality products at very genuine prices. (Read more about Cottonseed Oil Machine >>)

Typically the type of oil tank is selected based upon capacity and the vapor pressure of the product being stored. The working pressure required depends upon the vapor pressure, and the temperature variations of the liquid’s surface.

Cotton Seed Oil Tank in Solvent Extraction Plant

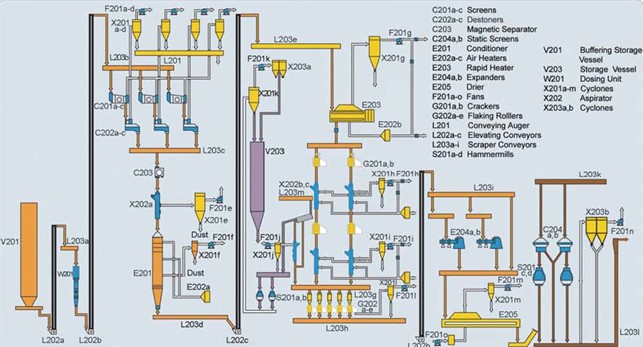

The solvent extraction plant is designed to extract oil directly from oilseeds containing less than 20 percent oil after flaking, such as soybeans. The process is also used for prepressed or fully pressed cake derived from oilseeds containing more than 20 percent oil to include sunflower seeds, peanuts, cotton seeds, palm kernels, canola, copra, castor and others. Extraction is conducted on prepared seeds or, in the case of high oil content seeds, the cakes obtained through pre-pressing.

Edible cooking oil extraction has been commercialized today where different chemical processes are used to come up with these edible oils. There are many plant matters that are used to produce edible oils such as sunflower, almonds, coconuts, soy beans, palm kernels and peanuts among others. The extraction is relatively very simple and one can easily do the extraction at home as long as you have a press machine.

Edible cooking oil extraction has been commercialized today where different chemical processes are used to come up with these edible oils. There are many plant matters that are used to produce edible oils such as sunflower, almonds, coconuts, soy beans, palm kernels and peanuts among others. The extraction is relatively very simple and one can easily do the extraction at home as long as you have a press machine.

There are different types of vegetables that contain oils and all that is required is for them to be oppressed for the crude oil to be removed. When you visit edibleoilextraction.com, you will get to know the various processes that can be used in making the extraction procedure effective. Vegetable oil processing is important and it will tend to vary depending on the type of vegetable oil that will either be used for food or simply as fuel. Keep in mind that, vegetable oil is processed with an aim of becoming a food product at the end of it all.

There are different types of vegetables that contain oils and all that is required is for them to be oppressed for the crude oil to be removed. When you visit edibleoilextraction.com, you will get to know the various processes that can be used in making the extraction procedure effective. Vegetable oil processing is important and it will tend to vary depending on the type of vegetable oil that will either be used for food or simply as fuel. Keep in mind that, vegetable oil is processed with an aim of becoming a food product at the end of it all. In vegetable oil processing, a feedstock is used and as such, it is important for it to be cleaned thoroughly so that any sand or dirt can be removed. Washing with clean water is also required to ensure the feedstock is clean. Ensure that the feedstock is properly dry so that moisture is not present during the processing. Presence of moisture during this processing can make the oil to be cloudy and at the same time harder to process. It is for this reason that you need to ensure the feedstock is completely dry before you can commence the processing. This in turn will make your processing effective and worthwhile.

In vegetable oil processing, a feedstock is used and as such, it is important for it to be cleaned thoroughly so that any sand or dirt can be removed. Washing with clean water is also required to ensure the feedstock is clean. Ensure that the feedstock is properly dry so that moisture is not present during the processing. Presence of moisture during this processing can make the oil to be cloudy and at the same time harder to process. It is for this reason that you need to ensure the feedstock is completely dry before you can commence the processing. This in turn will make your processing effective and worthwhile.

These edible oils include vegetable oils and animal oils and fats. In the process of oil extraction in order to get vegetable oils, the processing is done on soya beans, peanuts, cotton seeds, flaxseeds, safflower seeds and sesame seeds among others. Once an extraction has been down from these plants, we get the last product which is vegetable oils. For the animal oils and fats, trimming of freshly slaughtered animals is done to get these oils.

These edible oils include vegetable oils and animal oils and fats. In the process of oil extraction in order to get vegetable oils, the processing is done on soya beans, peanuts, cotton seeds, flaxseeds, safflower seeds and sesame seeds among others. Once an extraction has been down from these plants, we get the last product which is vegetable oils. For the animal oils and fats, trimming of freshly slaughtered animals is done to get these oils. At the edibleoilextraction.com, you will learn that the most basic thing behind edible oil extraction is to simply extract oil from a seed using a certain organic solvent. It is important to note that the correct concentration is required to make this effective. However, having the wrong concentration is a sure fact that the extraction will not come up as required. It is therefore important to put a lot of emphasis on the concentration that is to be used in the oil extraction.

At the edibleoilextraction.com, you will learn that the most basic thing behind edible oil extraction is to simply extract oil from a seed using a certain organic solvent. It is important to note that the correct concentration is required to make this effective. However, having the wrong concentration is a sure fact that the extraction will not come up as required. It is therefore important to put a lot of emphasis on the concentration that is to be used in the oil extraction.